JIANGSU TIANCHENG GROUP LIMITED

Yaoguan Town, Changzhou City, Jiangsu Province,China

+86-519-88387662

+86-519-85121683

steel_tube

steeltube.china

Tiancheng_Group

josen_dong

info@tiancheng.org

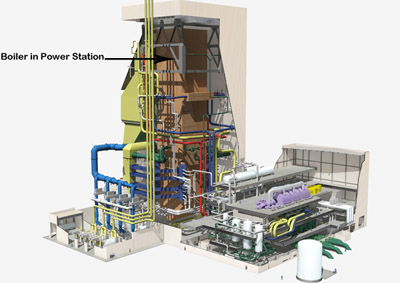

In power station construction, boiler tubes and pipes are used in large quantities, especially 20G boiler steel tube, ASTM/ASME boiler tubes for various applications.

20G Boiler Steel Tube Application:

20G boiler steel tube is mainly used in the manufacture of high pressure and over pressure steam boiler pipes. With seamless steel tube covers high quality carbon structural steel, alloy steel and stainless heat resistant steel, as boiler tube works in high temperature and high pressure environment, high temperature flue gas and steam will cause the action of oxidation and corrosion, steel pipe product for boiler purpose shall has high rupture strength, high oxidation resistance, and good organizational stability.

Industrial Boiler in Power Plant

Industrial Boiler in Power PlantMain boiler pipe steel grades are: high quality carbon structural steel grade 20G、20MnG、25MnG; 15 MoG, alloy structural steel grade 15MoG、20MoG、12CrMoG、15CrMoG、12Cr2MoG、12CrMoVG、12Cr3MoVSiTiB, etc; Heat resistant steel rust 1Cr18Ni9、1Cr18Ni11Nb20G commonly used high pressure boiler tube, in addition to ensure that the chemical composition and mechanical properties to do hydrostatic test, flaring, flattening test. Steel tube shall be delivered at heat treatment state. In addition, the microstructure and grain size, the decarburization layer of finished steel boiler pipe also has certain requirements.

Boiler Steel Tube Features:

20G boiler steel tube is included in GB5310 steel grade (foreign corresponding brand: Germany ST45.8, Japan STB42, the United States SA106B), as the most common boiler steel pipe, it has the same chemical composition and mechanical properties with 20G steel plate. The steel has a certain temperature and high temperature strength, low carbon content, better plasticity and toughness, good cold and hot forming and welding performance. 20 g steel pipe is mainly used in the manufacture of high pressure boiler tube and higher parameters, low-temperature superheater, reheater, economizer and water wall, etc.

Small diameter tube wall temperature of 500 ℃ or less, as well as the water wall tube, heating tube economizer tube.

Large diameter pipe do wall temperature of 450 ℃ or less steam pipes, header (economizer, water wall, low temperature superheater and reheater header).

Steel Boiler Tube

Steel Boiler TubeMedium temperature 450 ℃ or less pipeline fittings, etc. As carbon steel will produce graphitization during the long running above 450 ℃, long-term highest use temperature limit of the heating surface pipe is best under 450 ℃. In this temperature range, its strength can meet the requirements of superheater and steam pipe, and has good oxidation resistance, plastic toughness, weldability and good hot and cold processing performance, has a wide application in boiler tube project.

| Steel Grade | yield strength | Tensile Strength | Elongation% | Impact (J)10*10 | Grain Size | Hardness | Structure |

|---|---|---|---|---|---|---|---|

| 20G | ≥245MPa | 410~550MPa | L≥24T≥22 | L≥40T≥27 | 4~10L | F+P | |

| SA-106B | ≥240MPa | ≥415MPa | L≥30 | L≥35 | ≥4 L | 123-187 | F+P |

| SA-106C | ≥275MPa | ≥485MPa | L≥30 | L≥35 | ≥4 L | 147-187 | F+P |

| SA-210C | ≥275MPa | ≥485MPa | L≥30 | 4~9 L | ≤179HBW | F+P | |

| 15CrMoG | ≥295MPa | 440~640MPa | L≥21T≥19 | L≥40T≥27 | 4~10 L | F+P(B) | |

| 12Cr1MoVG | ≥255MPa | 470~640MPa | L≥21T≥19 | L≥40T≥27 | 4~10 L | F+P+B | |

| P11 | ≥205MPa | ≥425MPa | L≥30 | T≥27 | 4~10 L | 125-179 | F+P+B |

| P12 | ≥220MPa | ≥415MPa | T≥30 | T≥35 | 4~10 L | 125-179 | F+P(B) |

| P22 | ≥205MPa | ≥425MPa | L≥22 | T≥27 | 4~10 L | 125-179 | F+P(B) |

| P91 | ≥415MPa | 595~830MPa | T≥20 | T≥40 | 4~10 L | ≤250HB or ≤25HRC | F+P(B) |

Chemical Composition Comparsion Table of Boiler Steel Tube:

| Steel Grade | C | Mn | Si | Cr | Mo | Cu | S | P | Al | V | Ni |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 20G | 0.17~0.24 | 0.35~0.65 | 0.17~0.37 | ≤0.25 | ≤0.15 | ≤0.20 | ≤0.02 | ≤0.025 | ≤0.01 | ≤0.08 | ≤0.25 |

| SA-106B | 0.20~0.25 | 0.65~1.0 | 0.17~0.35 | ≤0.25 | ≤0.15 | ≤0.20 | ≤0.015 | ≤0.02 | ≤0.02 | ≤0.08 | ≤0.25 |

| SA-106C | 0.20~0.25 | 0.65~1.0 | 0.17~0.35 | ≤0.25 | ≤0.15 | ≤0.20 | ≤0.015 | ≤0.02 | ≤0.02 | ≤0.08 | ≤0.25 |

| 15CrMoG | 0.12~0.18 | 0.40~0.70 | 0.17~0.37 | 0.90~1.10 | 0.40~0.55 | ≤0.20 | ≤0.02 | ≤0.025 | ≤0.02 | … | ≤0.30 |

| 12Cr1MoVG | 0.10~0.15 | 0.50~0.70 | 0.17~0.37 | 0.90~1.20 | 0.25~0.35 | ≤0.20 | ≤0.015 | ≤0.02 | 0.005~0.040 | 0.2~0.3 | ≤0.25 |

| P11 | 0.07~0.15 | 0.30~0.60 | 0.50~1.00 | 1.00~1.50 | 0.44~0.65 | ≤0.20 | ≤0.02 | ≤0.025 | ≤0.025 | … | ≤0.30 |

| P12 | 0.07~0.15 | 0.35~0.61 | ≤0.50 | 0.80~1.25 | 0.44~0.65 | 0.05~0.15 | 0.05~0.15 | 0.05~0.15 | 0.05~0.15 | 0.05~0.15 | 0.05~0.15 |

| P22 | 0.07~0.15 | 0.30~0.60 | 0.20~0.50 | 1.90~2.60 | 0.87~1.13 | ≤0.20 | ≤0.02 | ≤0.025 | ≤0.025 | ≤0.09 | ≤0.33 |

| P91 | 0.08~0.12 | 0.30~0.60 | 0.20~0.50 | 8.0~9.5 | 0.85~1.05 | ≤0.20 | ≤0.01 | ≤0.020 | ≤0.01 | 0.18~0.25 | ≤0.40 |

Contact us now if you're looking for steel tubes for boiler construction for power plant, sales team of Ourway-Tiancheng is always ready to offer you the high quality product with lowest price!